3D Printed 316 Stainless Steel

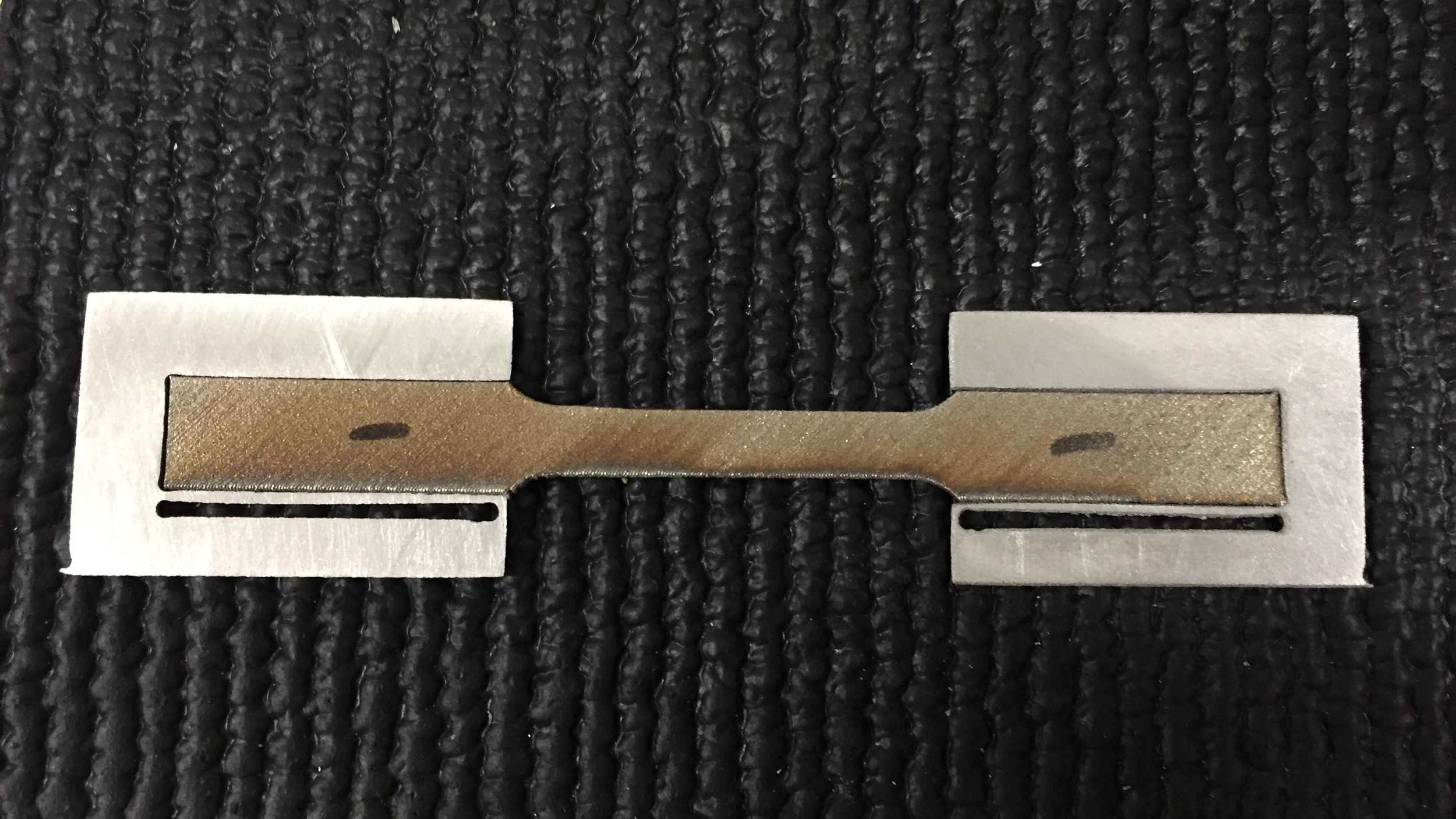

The goal of this experiment was to test thin metal 3D printed specimens in tension until failure. All samples were tested “as printed” or “as cut” with the exception of removing support material with pliers.

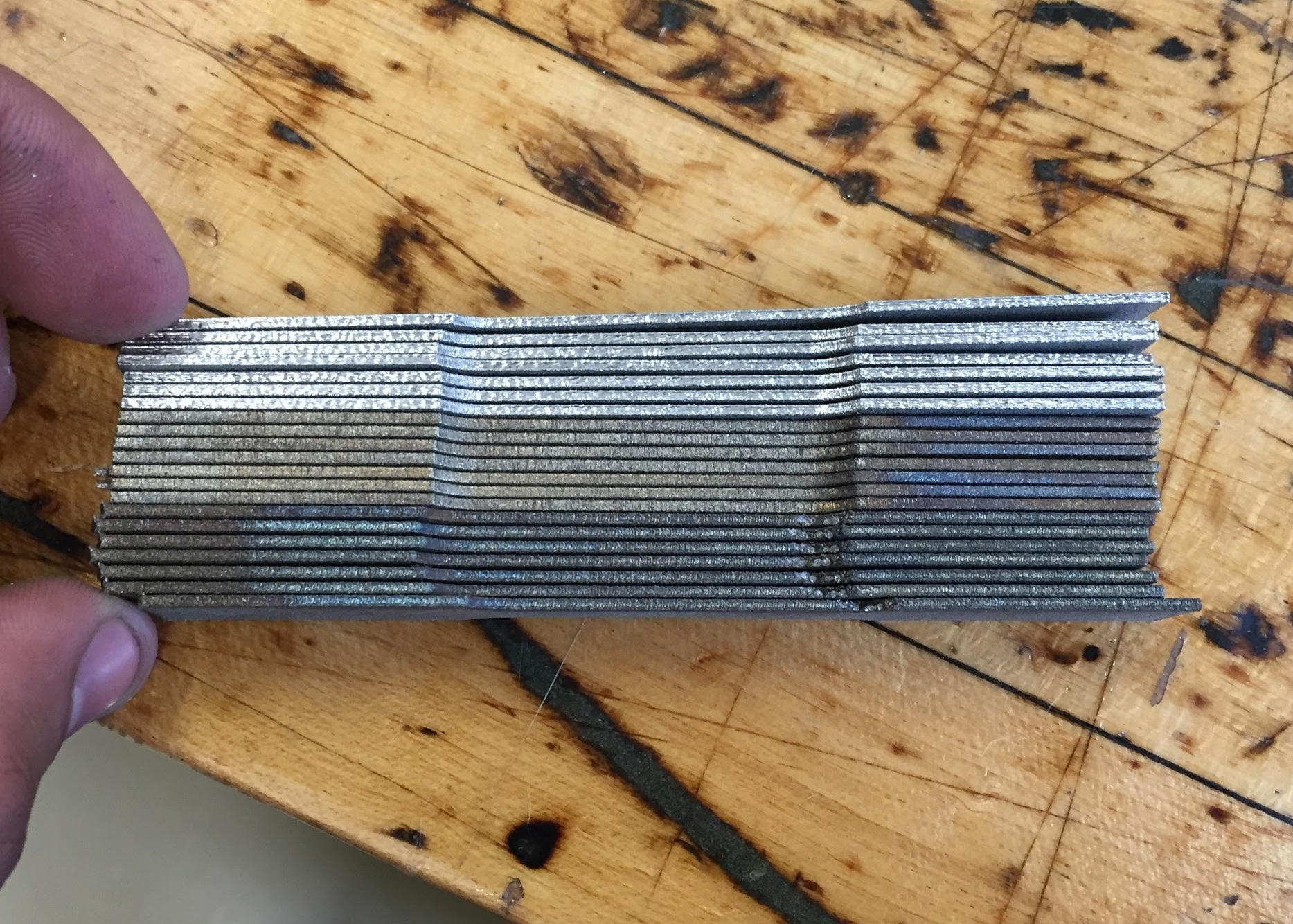

The samples were intended to be 1 mm thick (.039”) but as printed measured .049”-.051”. The comparison, traditionally manufactured stainless, was .048” but all data was converted to stress so that cross sectional area was factored into the values.

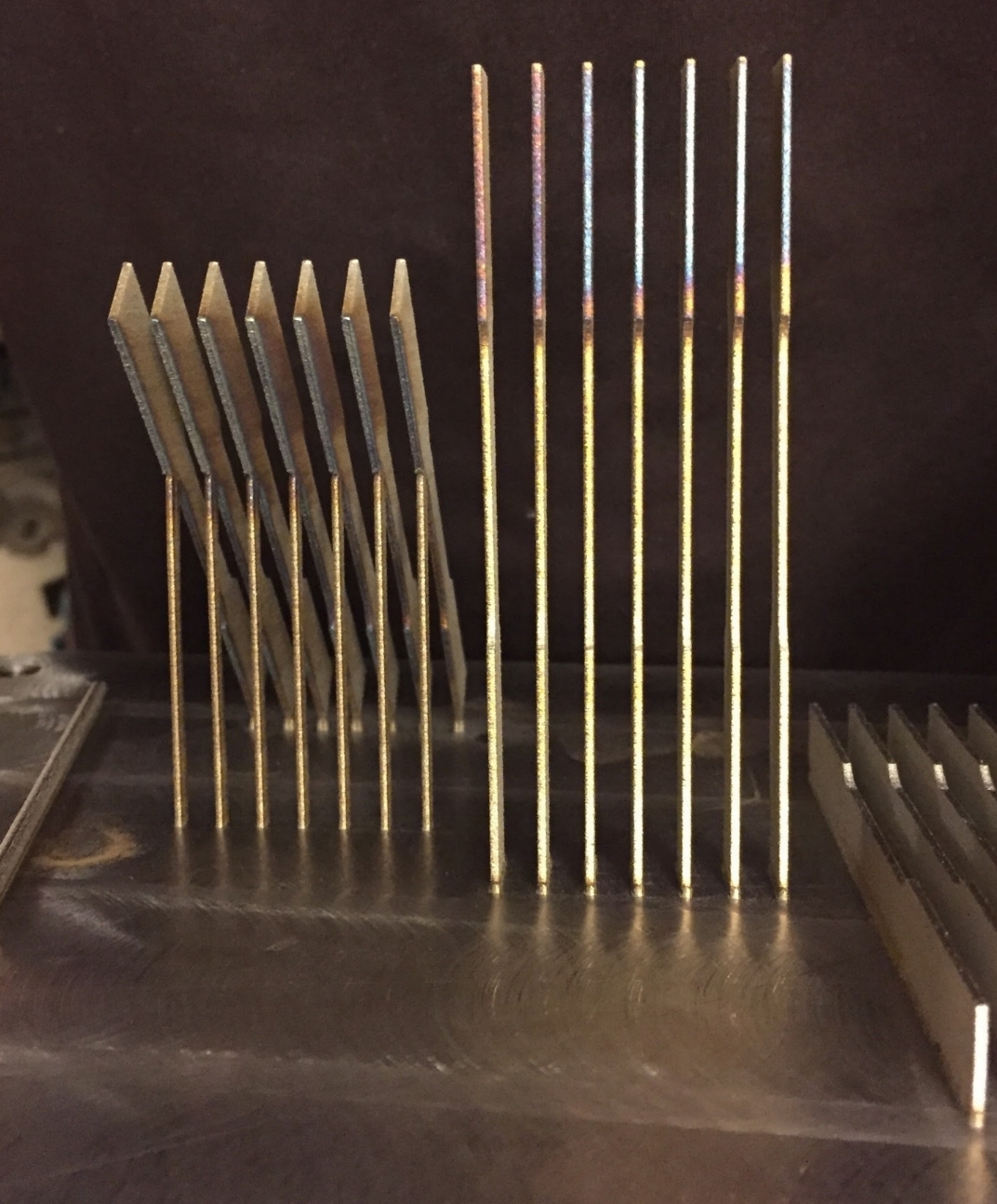

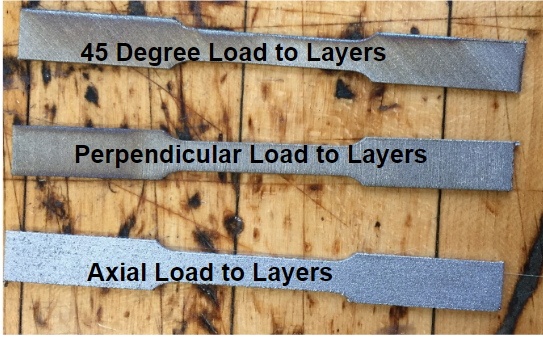

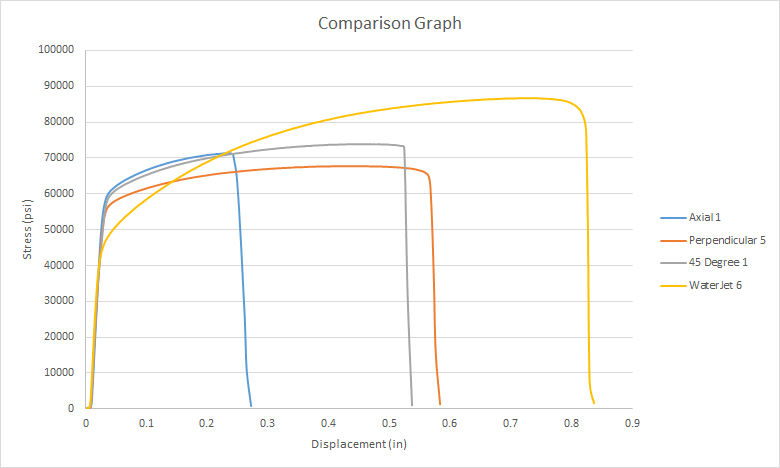

Three different print orientations were used: loading perpendicular to the layer lines, loading axially to the layer lines, and loading at a 45 degree angle to the layer lines. The axial loading was printed with the part lying down horizontally, the perpendicular loading was printed with the parts vertically, and the 45's printed at a 45 degree angle.

From the results of our tests, we concluded that a part made from 3D printed 316 stainless will perform to the desired results provided that the stresses on the part are kept in the elastic region. This is determined based on the fact that even the poorest performing 3D printed sample, perpendicular orientation, maintains a yield strength of approximately 25% stronger than the baseline certified 316 stainless steel.